A. Function of Aquaflex - Felt View System

FeltView is a continuous online measurement of felt moisture, permeability and felt temperature. Conventional handheld measurement system only provide rough snapshots of the life of a felt. Only by the complete recording of time, position and measured values can conclusions be recognized about the causes of the felt changes. Necessary countermeasures can thus be initiated early to ensure a long-term perfect conditioning of the felt. The FeltView system is a measuring system with highest positioning accuracy. The pneumatic contact pressure of the measuring head on the felt ensures optimum accuracy and reproducibility of the measurements..

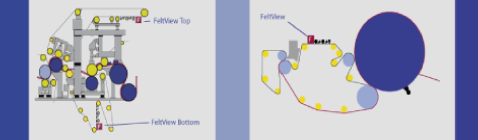

Fig. 1 Installation positions in the press section

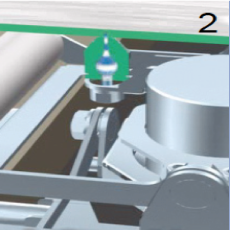

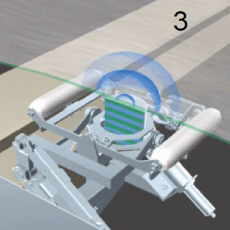

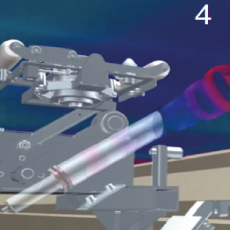

Fig. 2 FVS: 1. Measuring beam, 2. Permeability nozzle , 3. moisture-, 4. temperature measurement

C. The benefits of Aquaflex Felt View System

-

The vacuum box performance can be reliably matched to the condition of the felt (Energy savings up to 15 % - real experience!)

-

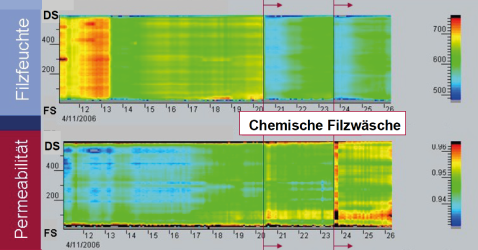

The necessary use of a chemical cleaning can be determined exactly and its effect can be checked immediately.

-

In combination with the Duo Cleaner a profile cleaning is possible. The evaluation of the FeltView measurement data shows the area of contamination in the felt, which should then be cleaned more intensively with the DuoCleaner.

-

The supplied quality from the felt supplier can always be checked reliable.

-

Reproducible measurement results are only possible if the human does not manually guide the measurement system

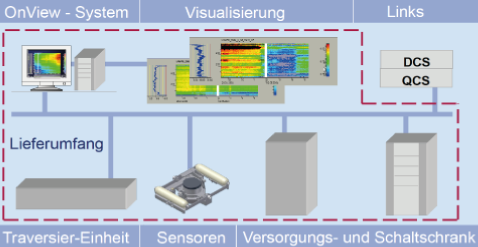

Fig. 3 The Felt View System consists of:

- Measure sensor with guide beam

- Visualization: presentation of results/p>

- Control: sensors, traverse, pressure generator

- Communication - Memory (Trend)

B. The user interface - Color - Map :

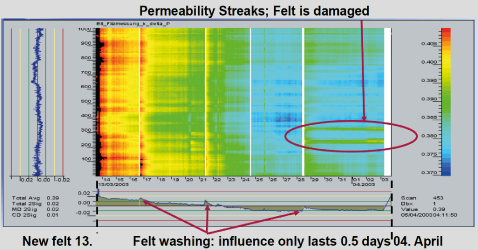

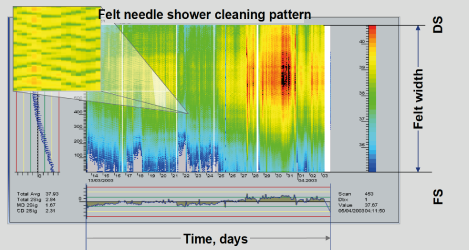

• Analysis of a permeability color map:

• Analysis of a permeability color map:

In the permeability color map shown above, two stripes are clearly visible (red ellipse). These stripes were also visible in m paper! The beginning of the banding started after the PM standstill (white vertical strip)! The timing of the formation of this strip is very important for the error analysis of a paper machine.

Immediately after the felt wash (red arrow), the permeability has improved for a short time. But the older the felt became, the shorter the effect of the wash has made noticeable, the color map representation shows very quickly the old color pattern.

The showerspray water often does not have the same temperature as the felt. Therefore, the felt cools at the locations where the needle jet nozzles have an influence. The superimposition of the felt, spray tube and measuring head movement results in an interference pattern, as shown enlarged above. In this way, e.g. detect clogged nozzles

Visualization of the measurement results: before and after the chemical wash